Showing posts with label macor. Show all posts

Showing posts with label macor. Show all posts

Macor Machinable Glass Ceramic in Lamp Reflectors

As a substrate and reflector in high-intensity lamps, macor Machinable glass-ceramic has enough strong thermal properties. Glass-ceramics are excellent elements in heat-resistant lamps and work great as reflectors in high-pressure explosion lamps. Laser decay glasses are available in both Macor MGC Machinable Glass Ceramic and Glazed ultra-white alumina.

The use of the before-mentioned lamps is to project pictures using explosions of high-pressure electrical curves to create a light emission of extremely high intensity. This is utilised for digital data projection in every type of electronic equipment which can range from a hand-held sensor or a smart tool to a huge television screen.

The essential requirement in such a set-up is the glasses continue steady at the extremely high temperatures required to create an illustration of high brightness and stable colour on a collecting screen. These reflectors and their substrates have to perform at temperatures regularly above 550 degrees Celsius. This is considerably above the melting temperature of borosilicate glass; the normal glass product used in electrical equipment screens.

Besides, the reflector and its substrate must have a low thermal increase coefficient, since the process of turning a device on and off produces high thermal inclinations. In turn, these begin to deformation and ultimate rupture of a standard reflector and substrate because it extends and decreases in the produced heat. Also, the reflectors and substrates have to work as heat tubs. This signifies reflectors and substrates have to exchange the heat produced from the infra-red portion of the light spectrum apart from the light origin.

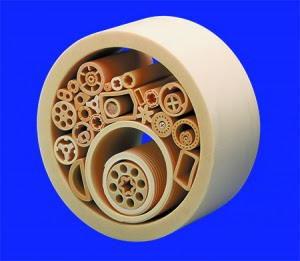

Macor glass-ceramics have all the mentioned physical properties. Also, it is composed of a smooth covering that does not necessitate any polishing after crystallisation. The combination of macor is actually known as fluorphlogopite mica that is included in a pattern of borosilicate glass. It is extremely machinable and can be made of many complicated shapes and patterns. It can be manufactured with regular machines for the metalworking and does not need users to spend on costly diamond-tipped tools.

Macor glass-ceramics is proficient in remaining constant continuously up to temperatures of 800 degrees Celsius, rising at the highest temperature of 1,000 degrees Celsius, if there is no pressure on it. Although it is chemically rebellious, particularly to powerful bases like alkaline soda. It's one weakness is that it is hit by halogens at high temperatures.

Applications of Technical Ceramics in Manufacturing Processes

Ceramics are the chemical solid made by the action of heat and subsequent cooling of the material. Ceramics material are usually described as chemical, non-metallic that are produced from powdered chemicals. Their particles are organized systematically and are in a compound composed of metallic and non-metallic components such as aluminium, oxygen, calcium, and more. Ceramics assents are classified into four categories such as technical, refractory, structural and white wares. There are bricks, tiles and bricks used for floors and roofs and these are included in structural ceramics. While refractory ceramics need to be up to extraordinary heat and they are employed in furnace insulation, gas fire radiant and glass making containers. The third is white wares include white ceramic objects usually found in the home in the form of tableware, cookware, pottery products, and appliances such as toilets and sinks. The last one is technical ceramic which is used in many purposes and its applications are from the space shuttle program to biomedical experiments.

Chemical applications of technical ceramics

Chemical applications of technical ceramics

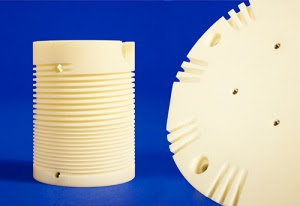

Most industrial ceramics are composed of metals and semi metals with the application of non-metals and the basic fundamental elements are oxides. Other materials that may be considered as ceramics are the components of silicon and carbon in the formation of rocks and graphite. In short, ceramics are more repellent to oxidation and corrosion than synthetic and minerals. Because of these chemical properties, the major applications of technical ceramics can be found in tubes, seals, and impellers.

Industrial wear applications of technical ceramics

Industrial ceramics are composites of light non-metals with more volatile elements or semi metals. Commonly, ceramics have low frequencies associated with metals. Also, many ceramics are quite hard and withstand wear and abrasion. So, the two of several industrial wear applications of technical ceramics are shot blast vents and paper de watering sheets.

Electrical resistance welding and ceramics

Ceramics present a broad spectrum of electrical conductivity. The appearance of free atoms in an oxide or silicate may give an increase to ionic conductivity, which rises in high heat. As ceramic weld roll is a metal forming product, it is used in electric friction welding.

Thermal applications of technical ceramics- Industrial ceramics or Machinable Glass Ceramics have a really high melting feature. They can maintain strength and stability to deformation under pressure at temperatures greater than many metals which can be detected. Thermocouple shield covers are used to measure the heat in aluminium plants and smelters.

Other applications of technical ceramics involve liners, pump plungers, valve, lift pins and many more.

Subscribe to:

Posts (Atom)

Popular Posts

-

Fracking is a general or slang term used for hydraulic fracturing. Hydraulic fracturing requires digging into the ground to get energy-rich ...

-

The capillary column for gas chromatography is essentially a very thin tube with the fixed point veneering the inner surface. In the bound...

-

Quartz heater is a popular type of infrared heater in which the heating element is surrounded by quartz tube . The infrared energy it emit...