Ceramics are the chemical solid made by the action of heat and subsequent cooling of the material. Ceramics material are usually described as chemical, non-metallic that are produced from powdered chemicals. Their particles are organized systematically and are in a compound composed of metallic and non-metallic components such as aluminium, oxygen, calcium, and more. Ceramics assents are classified into four categories such as technical, refractory, structural and white wares. There are bricks, tiles and bricks used for floors and roofs and these are included in structural ceramics. While refractory ceramics need to be up to extraordinary heat and they are employed in furnace insulation, gas fire radiant and glass making containers. The third is white wares include white ceramic objects usually found in the home in the form of tableware, cookware, pottery products, and appliances such as toilets and sinks. The last one is technical ceramic which is used in many purposes and its applications are from the space shuttle program to biomedical experiments.

Chemical applications of technical ceramics

Chemical applications of technical ceramics

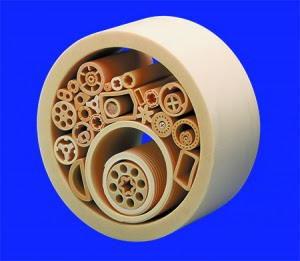

Most industrial ceramics are composed of metals and semi metals with the application of non-metals and the basic fundamental elements are oxides. Other materials that may be considered as ceramics are the components of silicon and carbon in the formation of rocks and graphite. In short, ceramics are more repellent to oxidation and corrosion than synthetic and minerals. Because of these chemical properties, the major applications of technical ceramics can be found in tubes, seals, and impellers.

Industrial wear applications of technical ceramics

Industrial ceramics are composites of light non-metals with more volatile elements or semi metals. Commonly, ceramics have low frequencies associated with metals. Also, many ceramics are quite hard and withstand wear and abrasion. So, the two of several industrial wear applications of technical ceramics are shot blast vents and paper de watering sheets.

Electrical resistance welding and ceramics

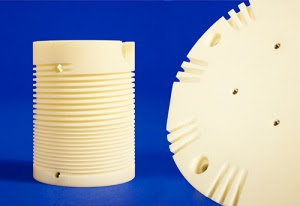

Ceramics present a broad spectrum of electrical conductivity. The appearance of free atoms in an oxide or silicate may give an increase to ionic conductivity, which rises in high heat. As ceramic weld roll is a metal forming product, it is used in electric friction welding.

Thermal applications of technical ceramics- Industrial ceramics or Machinable Glass Ceramics have a really high melting feature. They can maintain strength and stability to deformation under pressure at temperatures greater than many metals which can be detected. Thermocouple shield covers are used to measure the heat in aluminium plants and smelters.

Other applications of technical ceramics involve liners, pump plungers, valve, lift pins and many more.

Thank you so much for sharing this blog with us. It provides a collection of useful information. You obviously put a lot of effort into it. Glass Cutting Service From Valley Design.

ReplyDelete